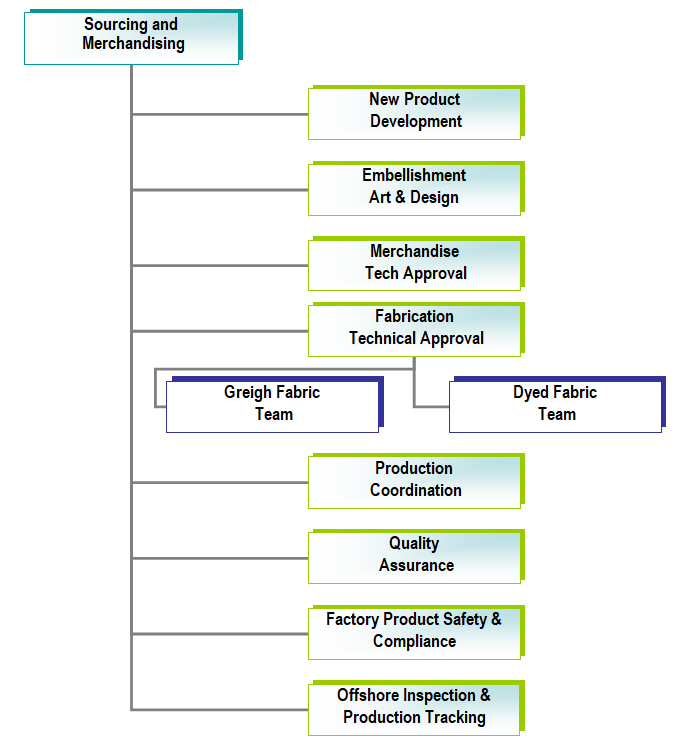

Our Organization, how we work ?

Apparel connection has developed a unique sourcing capability that enables it to manufacture products in factories located around the country with a very cost efficient manners, while at the same time maintaining highest standards of products quality and consistency to meet buyer’s requirement.

Quality is never an incident, it is always the result of high intention, sincere efforts, intelligent direction and skillful execution, it represents the wise choice of many alternatives.

The unique sourcing capability is achieved as a result of building state of the art designing capabilities, sophisticated engineering and sample making.

A global network of sourcing resources and an advanced / unique web-based specification and communication system.

Apparel connection New Development capability is a key asset of the company, enabling it to bring exciting / challenging and most typical processes and typical processes and typical product designs to our customers.

Having our own Product Development department equipped with latest technology sewing and finishing machines enable to produce 11th hour rush sampling programs and ship to valued customers over night for their urgent sales meet-ups & Photo shoots.

Our merchandisers, designers and embellishment teams are all dedicated to the best product development and creativity, focused to present particular line through resourceful channels.

Each multifunctional team has experienced designing people artists and product development managers capable to handle the entire product development process from beginning to end.

Our team uses state of the art CAD / Cam technology, we have all our merchandisers work extensively and use the internet and computer technologies to maintain our Leader ship through efficient communication system and technology that make ones work elegant.

Our Embellishment Dept Team coordinates all the time with Factories and Our Merchandisers during Productions to maintain the quality of embellishment, Printing or embroidery to meet customer’s specifications.

Ensure all samples are made with perfection and up to buyer’s specification and requirement.

- On-time sample submissions.

- To make targets of sample dates with customers.

- coordinates with factory and Merchandisers to help and make factory personnel/experts understand the technical aspects of a product as designed or required by customer.

- To ensure all fittings / construction / needle works and measurements are correctly followed.

Our fabrication departments contains following sub-divisions:

- In-House Technical Laboratory

- We check each and every dyed lot in our office to ensure best matching with shade consistency through our latest machineries and technically trained and literate staff.

- We have all kind of most updated testing methods and criteria’s related to the approval of specific stores.

- Mac Beth color solutions have provided us the light Box comprising of CWF-D 64–TL84–UV Lights.

- All imported washers and excusers which are industrial certified and accredited quarterly by the approved firms of accreditation.

- Technical Fabrication Unit

- We have complete individual teams handling our Greigh & Dyed Fabric separately.

- Greigh Fabric Team

- Ensures right stitch length and correct machines are selected for knitting the yarn, which will give best results of shrinkages in wet processing.

- To design the most spectacular / sophisticated and technical fabric.

- Jacquards / yarn dyed strippers / technical mesh / jacquard mesh / chain stitch jerseys are some examples of our innovations.

- Dyed Fabric Team

- Dyed lots shade bands, consistencies between the colors of every order.

- Checks fabric on JCP point 4 system.

- Assure every role matching through making individual dye load shade bands for consistency.

- Make sure that dyes / chemicals or colors being used during dyed are as per international testing standards, friendly to natural environment and causes no harms or effects to end user of these products.

- Handle every lot’s technical data related to the individual fabric i.e. shrinkage results, weight GSM, torque, color crocking, dry-wet, home laundering, following American Association of Textile Chemist and Colorist Standards.

- Core Fabrics

- All sorts of Knitted Fabrics.

- Fleece of All kinds.

- Jerseys of all kinds.

- All textured Fabrics.

- All kind of Yarn Dyed strippers.

- All kinds of Jacquard Fabrics.

- All Kind of Woven Fabrics.

Highly skilled & production / quality experienced personnel’s are kept and pointed zone wise, taking an over look of efficient right in time production & quality assurance upon quality inspectors, making sure that every step taken by each factory (zone wise) towards right direction and up to customer’s provided specifications and requirement.

Quality assurance department is divided 3 to 4 different teams lead by expert production coordinator / zone wise.

Each quality inspector has been assigned in individual factory to maintain quality and to perform the bridge services to connect all other departments of apparel connection with factory management and technical staff.

All quality inspectors report to production coordinators / quality assurance manager & superior chief operating officer.

Our all quality inspectors follow strict standards and perform inspection following AQL 2.4 standards. Whereas it could vary as per customer’s requirement.

We have highly experienced staff to meet the challenge of timely delivery of goods. Our staff make sure that Loading planning and container stuffing done in the light of CT-PAT guide lines.

From shipment planning to documents presentation we thoroughly monitor and guide our factories and suppliers to make proper documentation including LCs, Commercial Invoices, Packing List, Bill of Lading or Airwaybills as per our customers requirements and specifications.

To meet complete requirement of global industry and standards, we always seek to provide our customer the best.

To ensure the Factory compliances, Certification and social compliance audits, we have a complete team visiting all factories under our umbrella any time, maintaining their social / compliances work, talkative with their workers, making solutions to factory worker’s problems, solving each individual’s problems or making keen efforts for the betterment of skillful and the needy.

Our team perform un-announced audits of all sort to keep an eye to factory compliances / social responsibility and their safety / health and environment standards as well as documents procedures are in order or not.